How It Works

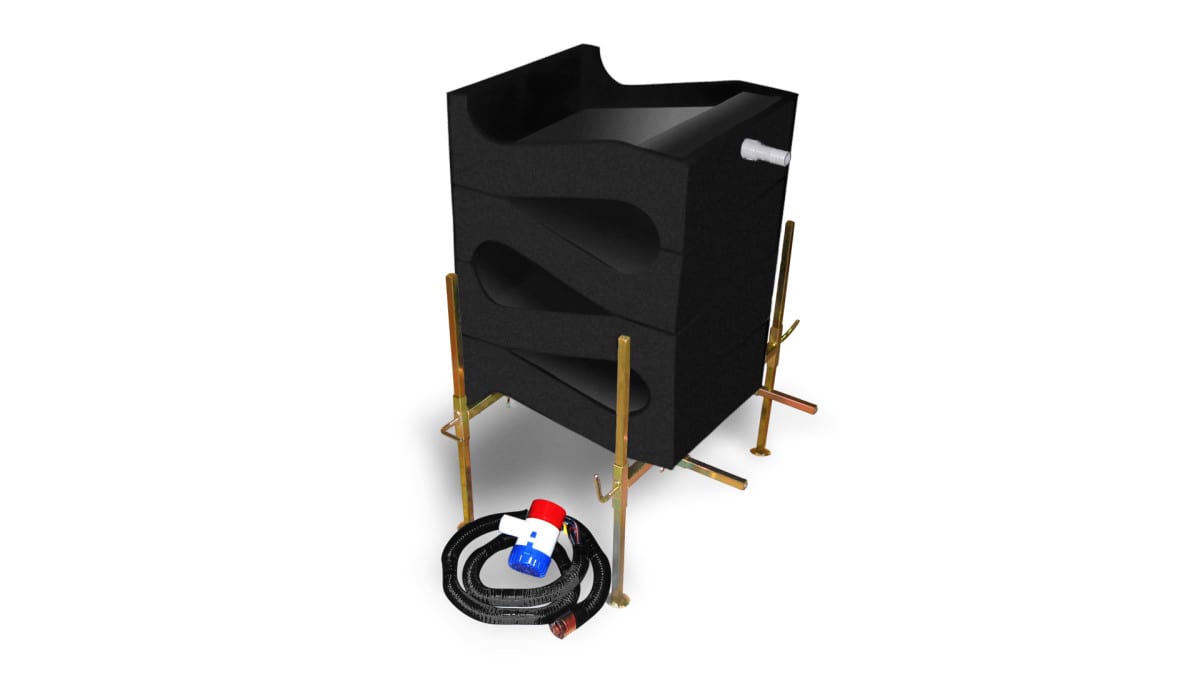

On this page we get into the unique technology that earned Gold Cube a U.S. Utility Patent. Many machines can process concentrates and get the gold however, instead of using a tablespoon, you can now use a large scoop of classified (1/8th) concentrates at a rate of 1,000 pound of material and reduce it to less than a coffee cup on highly concentrated gold and black sand! A good demonstration of this recently produced on a TV show called “Gold Trails” has Kevin Hoagland Panning a bucket of concentrates which took over an hour compared to the Gold Cube processing in less than 6 minutes. The Picture below is interactive so just hoover over different parts and explore the unique concepts of the Gold Cube. Prepare to be amazed!